.jpg)

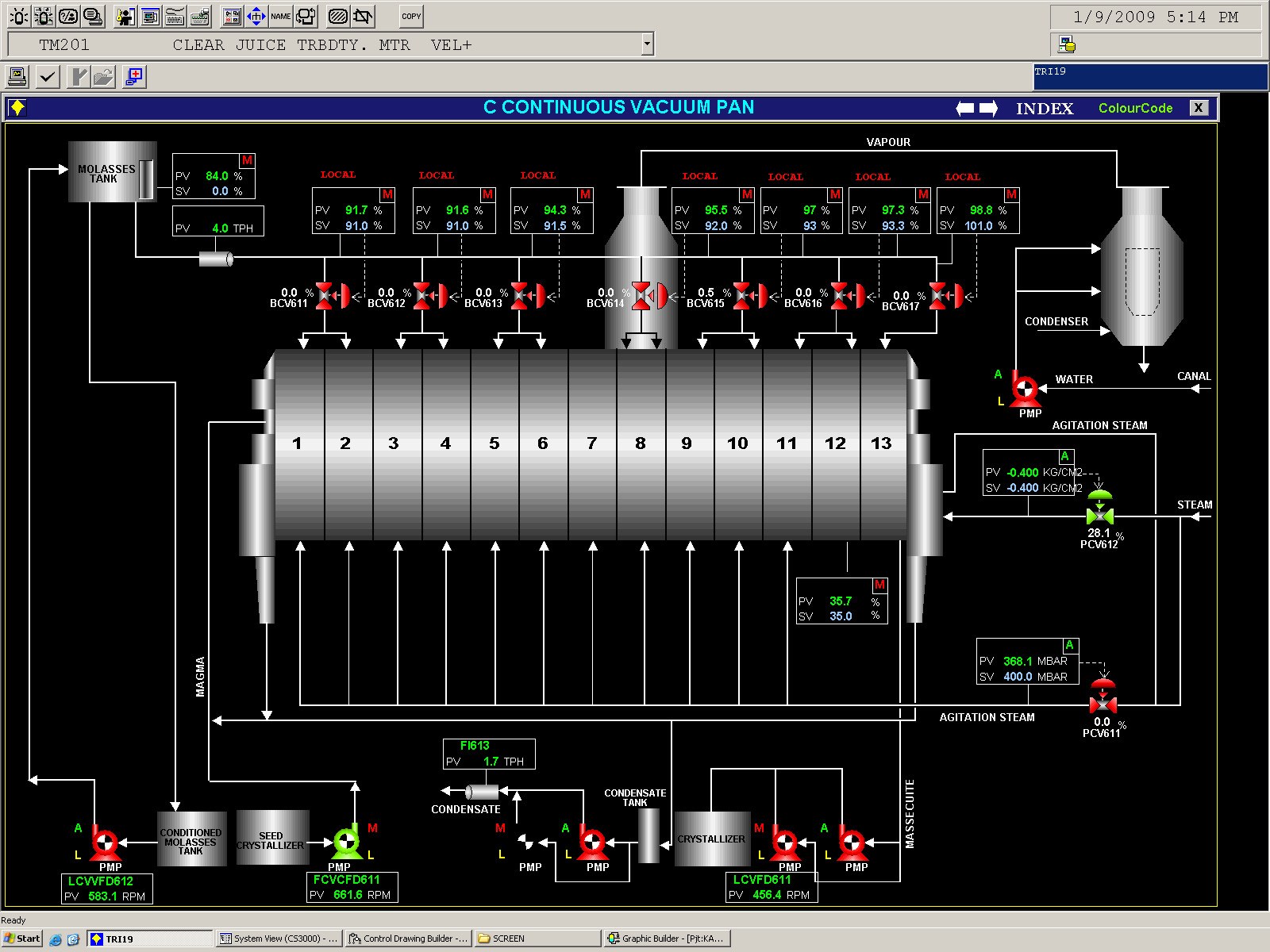

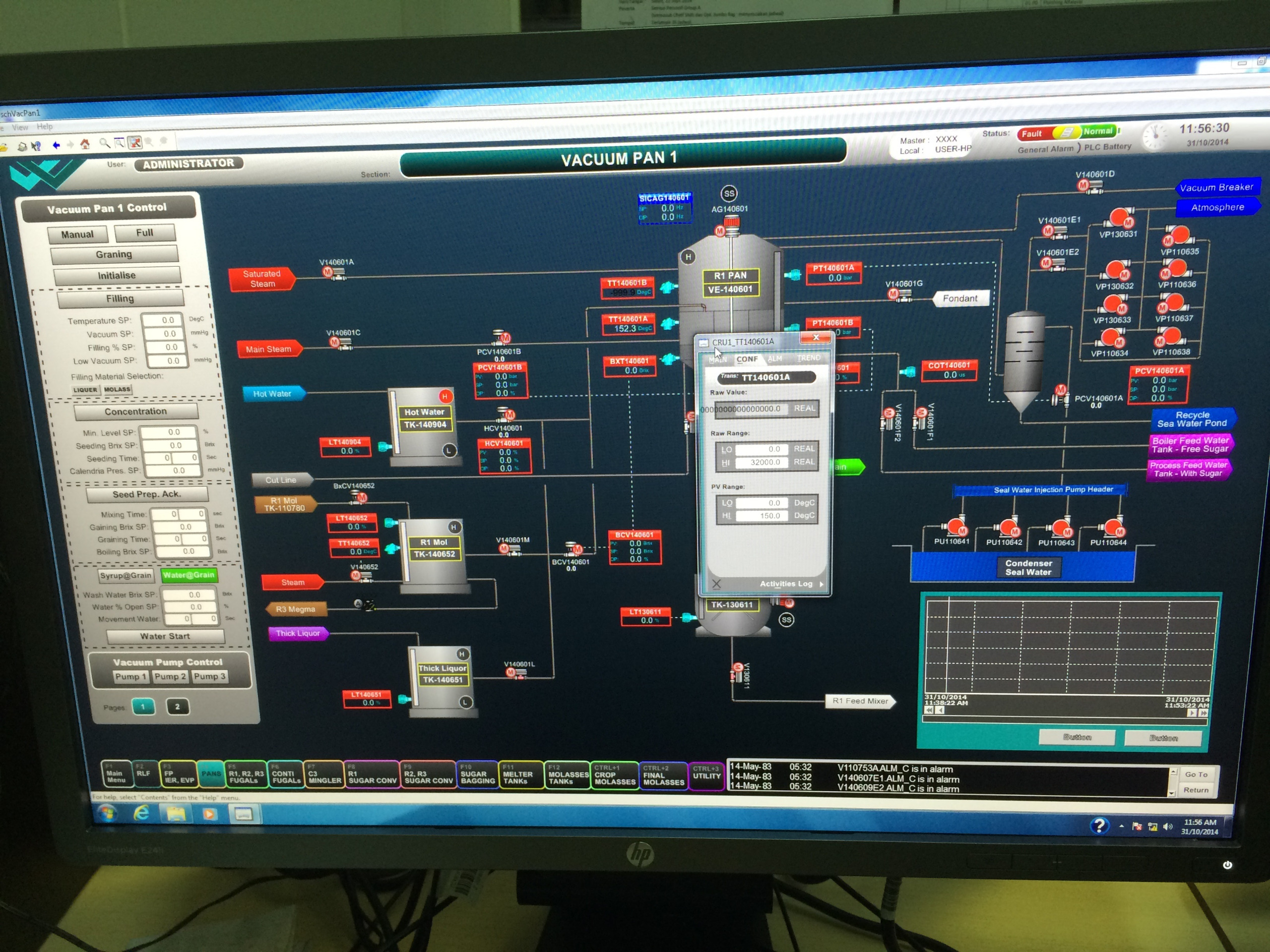

PAN Automation

Benefits of Energy Manangement System

- Enhanced Energy Efficiency: Maintains accurate brix levels for high-quality sugar output

- Reduced Operational Costs: Reduces steam consumption and energy usage through optimized cycle control

- Centralized Monitoring: Minimizes operator intervention, increasing process consistency

- Data-Driven Decisions: Enables centralized monitoring and real-time performance analysis via SCADA